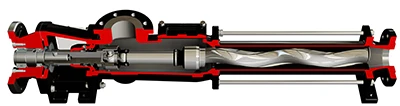

Modularity, flexibility, robust quality and options are strengths of the Nova Rotors standard flanged pump range. The unique geometry allows a large solids passage while the patented pin joint system and drive train options ensures a solid solution for puming sludges, slurries, waste products, effluent, polymers, oils and much more. The company’s strategy is totally focussed on achieving the best quality and standardisation of its processes and products applied to each specific sector. This choice enables Nova Rotors to produce innovative, highly technological products unique in the panorama of progressive cavity pumps.

Brand: Nova Rotors

Country of Origin: Italy

- Positive displacement.

- High repeatability on dosing applications.

- Can pump thick abrasive products.

- High suction ability.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in cast iron / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed and API versions.

- -40 to +150 deg C.

- Flows to 110m3/hr.

- Pressure to 48 bar.

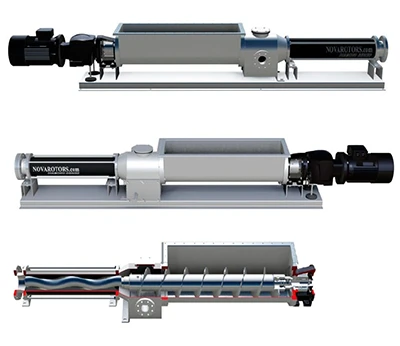

The open hopper pumps with hydraulic auger feed screw are ideal for handling high-consistency materials with a low degree of flowability and high solid content. Standard model equipped with rectangular hopper and an auger feed screw that moves the product to the hydraulic part. The length can be adapted to suit the application. Suitable for pumping materials with low flow-ability and up to 18% solids content which do not create or have a tendency to bridge.

All pumps can be made with a close coupled arrangement or a bearing unit arrangement and free bare shaft.

All pumps can be made with a close coupled arrangement or a bearing unit arrangement and free bare shaft.

Brand: Nova Rotors

Country of Origin: Italy

- Positive displacement.

- High repeatability on dosing applications.

- Can pump thick abrasive products.

- High suction ability.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in cast iron / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed and API versions.

- -40 to +150 deg C.

- Flows to 680 m3/hr.

- Pressure to 24 bar.

DHS series with hopper and an enlarged auger feed screw to convey directly the product to hydraulic part, are the ideal machines for pumping viscous and non-flowing, with a very high solids content. The DHS / JHS series are the hopper version with increased auger feed screw to the hydraulics.The length is customisable depending on application. The auger feed screw integrates joint protection. Suitable for pumping substances poorly flowing up to 35% of dry substance with high viscosity which don’t tend to form a bridge or blocks.

Brand: Nova Rotors

Country of Origin: Italy

- Positive displacement.

- High repeatability on dosing applications.

- Can pump thick abrasive products.

- Optional Ribbon auger feed screw.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in cast iron / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed and API versions.

- -40 to +150 deg C.

- Flows to 45 m3/hr.

- Pressure to 24 bar / 48 bar on request.

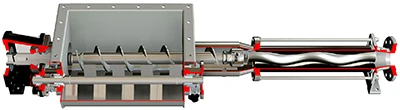

This model features a rectangular hopper and an enlarged auger feed screw that moves the product into the hydraulic part. Designed for the Biogas sector and pumping silage with the injection of phase liquid at the inlet to increase pump-ability of the solids. The separate inlet provides the connections for the injection of liquids and has a rectangular bottom for collecting any stones that might enter the hopper, thus avoiding damage to the hydraulic section. Moreover, a large additional inspection port is provided with quick couplings for easy removal of solid deposits from the inlet.

Brand: Nova Rotors

Country of Origin: Italy

- Customisable hopper lengths.

- Digestate injection port with stone catcher.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in carbon steel / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed.

- -40 to +150 deg C.

- Flows to 36 m3/hr.

- Pressure to 24 bar.

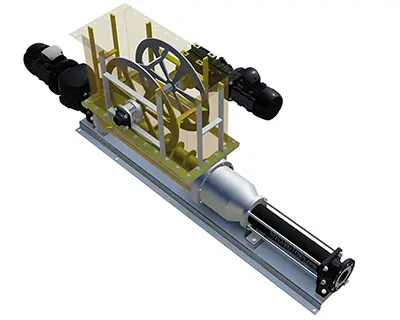

The DHS and JHS series are the hopper rectangular version with increased auger feed screw to the hydraulics.

Suitable to pumping non flowing product up to 40% of dry that tend to create bridge or blocks that shut out, is particularly useful in the pumping product that tend to deform under load (pseudo plastic behaviour) .

The auger feed screw integrates a special device for joint protection.

Brand: Nova Rotors

Country of Origin: Italy

- Bridgebreaker device Module “B” modular separately installable over the pump hopper.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in carbon steel / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed.

- -40 to +150 deg C.

- Flows to 45 m3/hr.

- Pressure to 24 bar.

The DHP and JHP series are the hopper version large with shaft bridge breaker and auger feed screw to the hydraulics. Suitable for pumping substances poorly flowing which tend to form a bridge. Particularly suitable for doughs or solids of considerable size compressible or compressible such as whole fruits and vegetables. This pump can be used in a wide area of food applications for grapes, whole fresh grapes, loaded with tomatoes in pieces or mixtures of the confectionery sector. Realised as standard in stainless steel AISI 304 or AISI 316. Design without death zone for an easy cleaning.

Brand: Nova Rotors

Country of Origin: Italy

- Driven Bridgebreaker paddle.

Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex). - Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in carbon steel / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed.

- -40 to +150 deg C.

- Flows to 105 m3/hr.

- Pressure to 24 bar.

The Vertical series is the ideal solution for pumping from wells or tanks. It is suitable for pumping viscous and non-viscous products as well as abrasive or aggressive ones. There are two standard configurations available: the short version and the long version.

The difference is in the length of the installation. The short version is compact, robust, easy to install, the long version instead allows installation in deep wells or tanks, and presents a complete series of dedicated optimisations such as the removable inlet for easy maintenance of the rotor, stator and coupling.

A fundamental characteristic is the support of the downhole support, with a guiding cone which makes the pump very stable and vibration free even in extreme conditions of use.

A fundamental characteristic is the support of the downhole support, with a guiding cone which makes the pump very stable and vibration free even in extreme conditions of use.

Brand: Nova Rotors

Country of Origin: Italy

- The stainless steel version is provided as a standard to the stator cover jacket which eliminates the need to use the tie rods and avoids contact with the product of the outer part of the stator avoiding the risk of corrosion.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in carbon steel / stainless steel / duplex / super duplex.

- Multiple seal systems including doubled flushed.

- -40 to +150 deg C.

- Flows to 110 m3/hr.

- Pressure to 12 bar on the standard version.