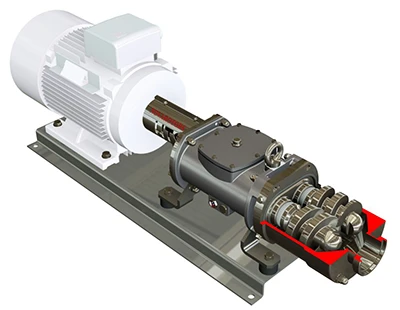

Nova Rotors HTS is new state of the art of hygenic twin screw technology. Designed to achieve the maximum level of sanitation for food and pharmaceutical market. We are proud of the extremely tough design in the product thanks to oversized shaft and bearing dimensions. Multiple sealing and materials options add to the flexibility of application that the HTS twin screw pumps can be applied to.

Brand: Nova Rotors

Country of Origin: Italy

- Positive displacement with low pulsation and high suction.

- Process and CIP with one compact pump.

- Able to handle solids and abrasive products.

- Various sealing options and range of FDA approved elastomers.

- Flows up to 160 m3/hr, Pressures to 25 bar.

- Suitable for very viscous liquids (up to 1.000.000cps).

- Temperatures from -40 to 130 Celsius.

The DX hygienic pump series is state of the art for the food, pharmaceutical, chemical and cosmetic industries. The complete sanitary design, with compliance in EHEDG and 3A standards, ensures maximum sanitisation. These pumps are top rated for “Clean In Place” and “Sterilising In Place” cleaning systems. The geometry of the pumps is designed specifically to allow drainage and avoid dead zones. Each component is manufactured with the highest level of finish and utmost cleanliness. The available materials and mechanical options make this probably the most versitile food industry progressive cavity pump on the market.

Brand: Nova Rotors

Country of Origin: Italy

- Positive displacement with low pulsation and high suction ability.

- High repeatability on dosing applications.

- Can pump thick abrasive products.

- Many set-up options e.g. Hopper screw feed, heated jackets, multible connection types.

- Choice of open or closed joints.

- Optional CIP port.

- Large range of sealing types and 15 different food grade elastomer options.

- Flows to 110m3/hr and Pressure to 24 bar STD/ 48 bar K8 series.

- Temperature from -40°C to 150°C.

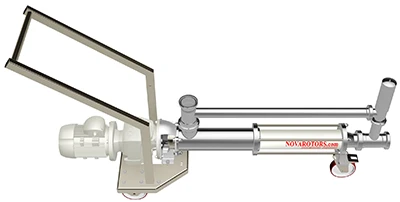

This model has a large eccentric hopper, with integrated trolley, ideal for the wine industry in conjunction with destemmers-crusher. For pumping crushed grapes with or without stems. Extremely compact standard construction with all parts made from AISI 304 stainless steel. The worm gear motor significantly reduces the pump’s footprint. The pump is supplied with a safety mesh on the hopper, protection guard for the drive system and a large handle that can accommodate electric panels and inverters. It can be supplied with a level probe on the hopper for automatic shutdown of the pump.

Brand: Nova Rotors

Country of Origin: Italy

- Complete packages with trolley and inverter controllers available.

- Rotor materials in AISI 420, AISI 304, AISI 316, F51(Duplex), F55 (Super Duplex).

- Rotor options – Induction hardening, coatings in HCP, ceramic and tungsten carbide.

- Stator elastomers NBR, food grade NBR, white NBR food grade, EPDM, EPDM food grade, white EPDM food grade, FPM, FPM food grade, HNBR, HNBR food, grade SYLICON.

- Housings in 304 / 316 stainless steel.

- Gland packed hopper shaft sealing.

- Suitable for CIP cleaning.

- Flows to 110 m3/hr.

- Pressure to 24 bar.